Customized Single Ended Heating Element Cartridge Heater for Pellet Stove Igniter

Overview Product Description Cartridge heater is cylindrical electrical heating elements. Protected with a stainless ste

Send your inquiryDESCRIPTION

Basic Info

| Tube Diameter | 6mm-30mm |

| Max Temperature | 870c(1600f) |

| Application | Gas, Oil, Water, Plastic |

| After-Sales Service Provided | Overseas Third-Party Support Available |

| Power | 50W-10kw |

| Resistance Heating Wire | Nicr 80/20 Wire |

| Insulation Resistance (Cold) | ≥ 500 MΩ |

| Length Tolerance | ±1 mm |

| Resistance Tolerance | +10%, -5% |

| Dia Tolerance | +0.05mm -0.1mm (+.002" -.004") |

| Voltage | 12-380V |

| Style | Cartridge |

| Transport Package | Paper Box |

| Specification | can be customized |

| Trademark | Cheri |

| Origin | China |

| HS Code | 8516800000 |

| Production Capacity | 10000000/Year |

Product Description

Cartridge heater is cylindrical electrical heating elements. Protected with a stainless steel sheath, their watt density can reach 63W/cm² and their operating temperature can go up to 800°C (1472°F) Mostly cartridge heater is used for heating up solids such as injection presses heating plates or various tools, cartridge heater can also be used for heating up water of gases under certain conditions. Widely used for manufacturing plastic and rubber parts in the car industry or in the food processing industry, etc . cartridge heaters are also commonly found in the chemical, electronics, medical equipment, packing and nuclear industries Various cartridge heater technologies are available. The choice of technology will depend on technical specifications required and the application. Unless you know exactly which product you are looking for, we will recommend you the best solution for your needs.

Product Description

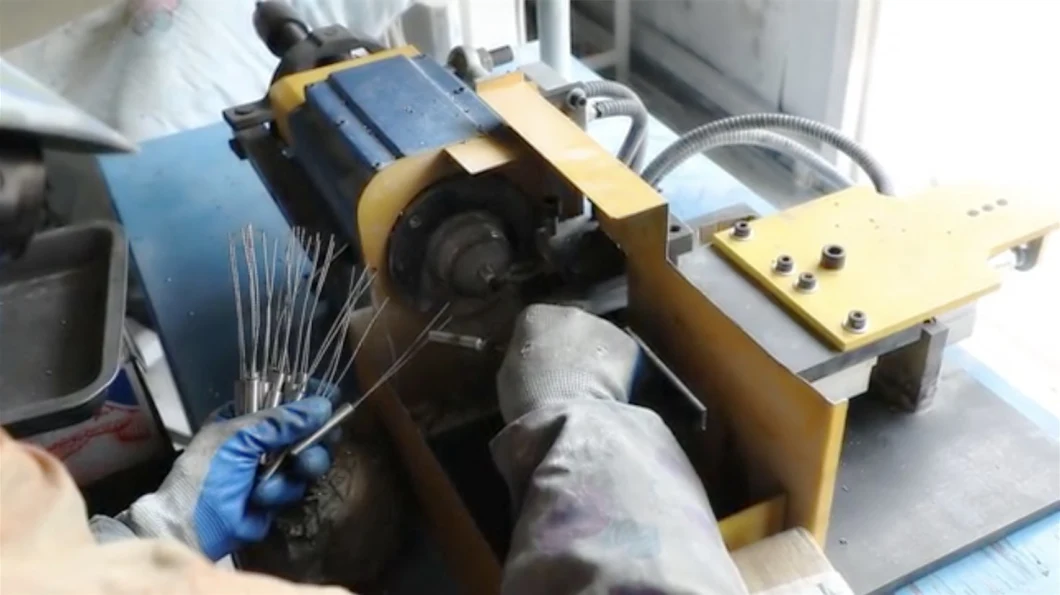

The heating part of the core of the cartridge heater is a nickel-chromium heat-resistant alloy wire, which is wound on a magnesium oxide core rod with excellent insulation and thermal conductivity. The heating wire and the shell are filled with magnesium oxide powder as an insulating material, and the air inside is compressed by the machine to make it into a whole.After the main body of the cartridge heater is completed, the fixing piece or thread can be installed according to the installation needs. The thread structure of the fixing piece is related to the heating tube installation method. Please contact our sales or technical personnel for the best solution.Due to the various shapes and specifications, it is impossible to display all of them. If you need to customize various special-shaped heating tubes, please contact customer service.

Product Parameters

1.Diameter 2.Volts and watts 3.Length 4.Type of lead wire 5.Select the outlet method

| Main material | |

| Heating wire | Ni8Cr20 nickel chromium wire |

| Insulation filling | High purity magnesium oxide powder |

| Shell (protection tube) | SS304,SS310S,SS316,TA1,Incoloy800(NCF800) |

| Lead | Silicone glass fiber (temperature resistance 250ºC) |

| Lead protection | Silicone fiberglass casing, metal braided hose, metal corrugated hose |

| Sealed end (sealing) | Ceramic/ceramic glue (temperature resistant 800ºC)Silicone rubber (temperature resistant 180ºC)Resin (temperature resistance 250ºC) |

Standard diameter size reference

Diameter in millimeters (mm): 2, 3, 4, 5, 6, 6.5, 8, 9.5, 10, 12, 12.5, 14, 15, 15.8, 16, 18, 19, 20, 25, 30, etc.Diameter inches (inch): 1/4", 3/8", 1/2", 5/8", 3/4", 1", etc. (Remarks: 1 inch = 25.4 mm)Note: High-power heating tubes are used in the mold, and mounting holes need to be reserved on the mold according to the size of the cartridge heater (or the outer diameter of the heating tube can be customized according to the size of the mounting hole). Please minimize the size of the heating tube and the mounting hole. Clearance. When machining mounting holes, the unilateral clearance is recommended to be within 0.05mm.

Our Advantages

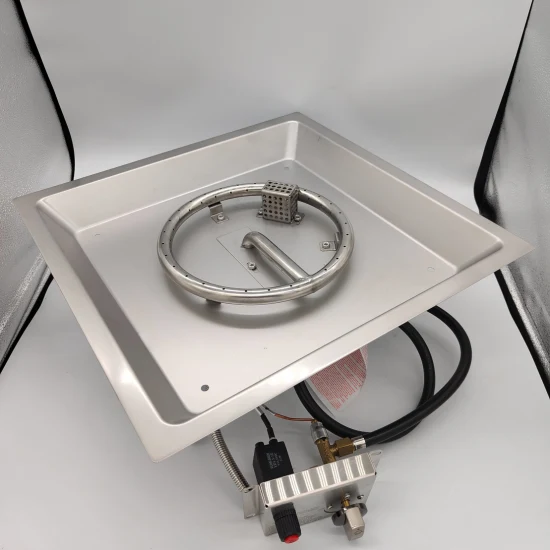

Product Photo&Application

Certifications

Order Information

1.About product ordering: The above product pictures are for reference only, drawings or samples must be provided for ordering.2.About the online price: the online price is the sample price, and the bulk price needs to be determined according tothe product drawing and quantity. Please continue to contact customer service or call the company phone to confirm.3.About delivery: nonstandard customized products have certain production processes, and the actual delivery date is subject to customer service confirmation.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.Q2: How long is your delivery time?

A: Generally it is 5-7 days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

Q3: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=10000USD, 50% T/T in advance ,balance before shipment.Q4: Is it OK to print my logo?

A: Yes. We also can OEM.